Oxygen Permeability Test of Package

In the 80s' of last century, recoverable glass bottles were mostly used in packages for soda soft drink, hot drink, mineral water, edible oil, seasons, wine & alcohol, fruit jam, etc in China's food market. Nowadays glass materials have been replaced by new materials such as plastic bottle, double-piece pop can, thee-piece pop can, paper-plastic-aluminium composite flexible packaging and so on. Demand of PET plastic bottles is increasing, and now it covers one of the leading shares in China's beverage packaging market. Since oxygen permeability of outer package directly affects product's shelf period, it is an urgent demand to perform standardized test upon oxygen permeability. The traditional way of testing oxygen permeability is to make one material into sheeting pattern. But we know that after one material is made into bottles the material's property will change and thickness of different parts of one bottle is various. Does the test data of film derived from package can represent the oxygen permeability of whole container? This maybe a hard question, Experts of packaging industry comment that it is not scientific to evaluate oxygen permeability of whole container using partial oxygen transmission rate. So how to get oxygen permeability of plastic containers has become a hard point in packaging industry.

1. Difficulties in package testing

Various dimensions. With the development of packaging production, various containers, big or small, have appeared in the market. They are often different in size, specification, volume and surface area, this makes permeability testing more difficult.

Difference in package holes. There are a good many kinds of containers with different styles of holes, moreover, holes design are changing with the development of market. Dimension and shape of a containers affect obviously the way of its fixing and sealing. So the connection between package hole and testing instrument is a puzzle in permeability testing.

Connection and sealing between test chamber and oxygen permeability tester . Three models of test chamber can be used: 1. Test without chamber: tests can only be performed in an open state (Oxygen concentration in test environment equals to that in laboratory environment.); 2.Using a plastic bag as test chamber: the plastic bag is sealed outside of the package to be tested. The way is hard to achieve oxygen circulation, the adjustment of oxygen concentration is limited and hard for seal around holes; 3. Special test chamber using barrier material of high performance: test chamber is separately sealed from the container with good seal and oxygen circulation can be achieved.

High requirements on laboratory environment temperature. This is because of sensor property and oxygen permeability test itself is greatly affected by laboratory environment.

2. Package Barrier Property Test in the World

For how to solve issues in container's barrier testing, barrier testing institutes and experts in the world have discussed a lot. Let's take standard ASTM F 1307-02 as an example, and explore the state of the art of package barrier test.

For ASTM F 1307-02 Standard Test Method for Oxygen Transmission Rate Through Dry Packages Using a Coulometric Sensor, its principle is completely the same as the test method for oxygen transmission rate through film using coulometric method.

This test method employs a coulometric oxygen sensor and associated equipment in an arrangement similar to that described in Test Method D 3985. Oxygen gas transmission rate (O2GTR) is determined after the package has been mounted on a test fixture and has equilibrated in the test environment. The package is mounted in such a way as to provide that the inside of the package is slowly purged by a stream of nitrogen while the outside of the package is exposed to a known concentration of oxygen.

The method by which a package is prepared for attachment to the instrument for testing depends upon the package shape, type, and test objectives. Whenever 100% oxygen is used to establish the test gradient, the operator should use care not to pressurize the oxygen-containing structure. (Oxygen partial pressure should be equal to the prevailing atmospheric pressure.)

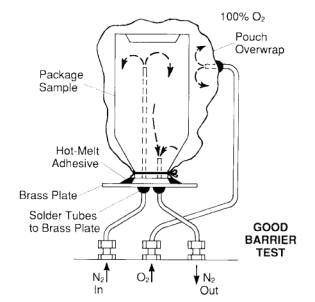

The fixing way shown in Figure 1 is applied to bottles, thermoformed plastic cups and tubs. The other fixing way, without pouch overwarp, is used to fix soft bags.

Figure1. Typical fixing way for plastic bottles and barrels

3. Labthink's Breakthrough in package barrier testing

TOY-C1 Package/Film Oxygen Permeability Tester developed by Labthink, which employs electrochemistry method and has dual testing functions for film and package. It conforms to standards ASTM F 1307, ASTM D 3985 etc. The test chamber is made of stainless steel with high smoothness quality. This makes samples easy to be sealed.

Feathers of TOY-C1 are as follows:

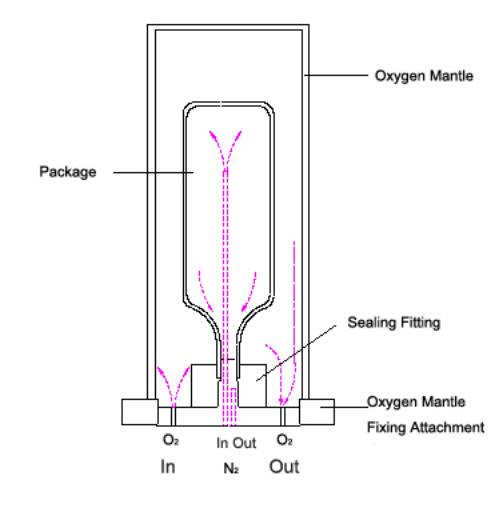

1. In the mode of package testing, oxygen chamber mantle is made of good barrier material and the chamber volume is big enough for plastic bottles and other packages with volume 2.5L or below, holes diameter size smaller than φ 120mm , height smaller than 360mm. If in the air test, the size of packages is not limited.

2. Unique fixing structure of package, beneficial to strong sealing for holes. Size of holes: inner diameter φ >13mm, outer diameter φ <50mm. For testing of packages such as bags and boxes, special fitting are provided for supporting. Sealing gas tubes are not needed, it's easy to use and replace samples.

3. Although test temperature is just laboratory ambient temperature, the special design of oxygen chamber is beneficial to keep the test ambient temperature stable.

Figure 2. Fixing method of packaging container for tests using TOY-C1

Figure 2 shows sample's fixing method for oxygen permeability test of plastic bottle using TOY-C1. “Labthink Laboratory Forum” will give more details on fixing methods and oxygen permeability tests of various kinds of packages.

Link:http://service.labthink.cn/en/article-Permeation-info-110118124.html

Labthink Copyrights. Please do not copy without permission! Please indicate source when copy.

Member Registration and Login In

| If you are already a member of us, please login in! | If you are not a member of us, please register for free! | ||

·Forget password? |

|

·Terms and Conditions If you have questions, please phone 86-531-85811021 |

|