An Outline of Operation of VAC-V1 Gas Permeability Tester

Labthink introduced its vacuum differential pressure permeability instrument -VAC-V1 Gas Permeability Tester in the second half of 2004. Over a short span of several months, this instrument has achieved remarkable sales record and will export to Southeast Asia soon. Before that, Labthink has already made successful achievement in the data comparison of international permeability testing. All these have promoted Labthink's position in international market of permeability instruments.

Based on international testing principle of differential pressure, VAC-V1 auto gas permeability tester is manufactured according to the standards of GB 1038, ISO 2556, ISO15105-1 and ASTM D1434, etc. It can be operated full automatically with the support of its powerful operating software. In order to help the users better understand and operate this instrument, this article provides the detailed procedures for film permeability testing of VAC-V1.

1.Test Preparation

Test preparation is of great significance for VAC-V1 testing, which includes test gas preparation, vacuum pump connection, specimen sampling & clamping and parameter setting of operating software.

1.1Test Gas

Prepare one bottle of 99.9% purified test gas and one relief valve that matches the gas source. VAC-V1 has no special choice for test gas, and any nontoxic and non-corrosive test gases are accepted. For permeability testing of special gas, the lab should be furnished with ventilating system.

1.2 Vacuum Pump

Vacuum connection, which will directly influence the vacuuming operation of lower and upper chambers, must be performed according to specifications provided by Labthink. To ensure the normal proceeding of testing, utilizing spare vacuum pump for other purposes is forbidden (for detailed requirements please refer to the instruction book).

1.3 Prepares and Clamp Specimen

Generally, specimen preparation and clamping can be divide into the following six steps: (1) sample with specimen cutter; (2) rotate handwheel to lift the upper testing chamber; (3) apply vacuum grease on specified area of lower testing chamber; (4) put filter paper in the central hole of lower chamber; (5) place the specimen; (6) rotate the handwheel to ensure the lower and upper chambers joint each other closely.

VAC-V1 has a series of accessories to facilitate the above procedures: specimen cutter, ester spread ring and localizer loop.

1.3.1Specimen Cutter

Operators can make specimen of ф 97mm easily by specimen cutter. Moreover, with the specimen cutter, surface state of specimen is effectively maintained effectively without being influenced by sampling operation.

1.3.2 Ester Spread Ring

The applying of vacuum grease on non-transmission area of lower testing chamber before specimen placement forms a vital part of specimen clamping. Vacuum grease can effectively prevent specimen edge from leaking and level lower testing chamber during the specimen attachment.

This procedure must be carefully operated because if vacuum grease is applied in gas transmission area, it is difficult to remove; and the grease will contaminate the testing area and influence testing results. Users can use the ester spread ring as an assistant tool to apply vacuum grease uniformly in specified area. The vacuum grease being chosen should be of good quality. Otherwise, the specimen surface may be impaired by tiny particles contained in poor quality vacuum grease.

It is true that only using ester spread ring to prevent edge leakage is not sufficient. To achieve a better sealing effect, two edge O rings are used in VAC-V1 to facilitate specimen sealing.

1.3.3 localizer loop

After completion of vacuum grease applying, set fitter paper in the central counterbored hole of lower chamber. Keep its edge away from vacuum grease. Then, use localizer loop to put the specimen in the center of lower testing chamber.

1.4 Parameter setting

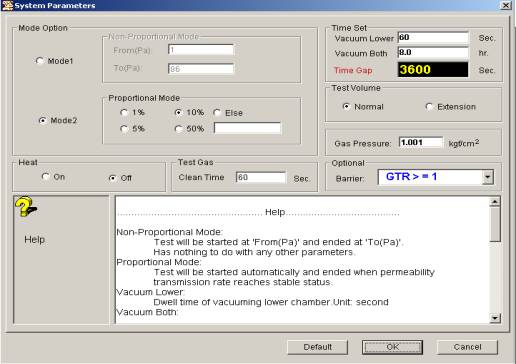

Fig .1. Parameter Setting Interface of VAC-V1 Operating Software

Operators can set all the parameters in system parameter setting interface (See fig. 1) of VAC-V1 operating software.

VAC-V1 has provided two testing modes: Non-proportional and proportional. Users can choose their modes in the mode interface. Generally, proportion mode can meet the requirements except when the specimen is of very good permeability. In terms of testing, there is no essential difference between proportional mode and non-proportional mode; the only difference is that the choice of appropriate mode can improve working efficiency.

Outgassing time setting includes the setting of lower chamber outgassing time as well as the setting of lower and upper chamber outgassing. The outgassing period of lower chamber is not a key parameter but it cannot be zero. Maintaining the system default setting of 60 seconds is recommended unless there is special requirement. Outgassing time of lower and upper chambers is a key parameter that can influence the test results. Please refer to the recommended values by Labthink for parameter setting.

2.Testing

Testing operation is very simple and fully intelligent. By clicking ‘test' icon in the main interface of operating software, the testing will automatically proceed without any manual operation. It has realized 24-hour all-whether working. Through the operating software, users can also see the testing data such as pressure-time curve, humidity-time curve, temperature-time curve and real time data.

3.Data processing

When the test has finished, gas transmission rate (GTR), diffusion coefficient, solubility coefficient and permeability coefficient will be directly presented (under proportional mode). In addition, VAC-V1 has a series of powerful data processing functions including classified data storage (software prompting after testing), testing report printing, manual data processing (manual calculating test result), data fitting and data mirror and resume. Among them, the data-fitting function is very useful. Those who are interested can refer to the article Method to Gain Film Permeability under Special Temperature - Permeability Parameter Fitting, which was updated on January the tenth, 2005 in Labthink Lab forum.

Note: Unfinished matters should refer to the instruction book of VAC-V1 Gas Permeability Tester.

Link:http://service.labthink.cn/en/article-Permeation-info-110118118.html

Labthink Copyrights. Please do not copy without permission! Please indicate source when copy.

Member Registration and Login In

| If you are already a member of us, please login in! | If you are not a member of us, please register for free! | ||

·Forget password? |

|

·Terms and Conditions If you have questions, please phone 86-531-85811021 |

|