As the theoretical research on package is developing, people have discovered that the contents of nitrogen gas, carbon dioxide and other gases in inner package could also impose influences on the content, with food and medicine being the most sensitive.

1.Packing Functions of Nitrogen Gas and Modified Gas Package

For the reason that gas density of oxygen, carbon dioxide and so on can cause quality deterioration of food and medicine, vacuum packing (i.e. to extract inner gases with vacuum equipment after the plastic film package of products is finished) was originally adopted to reduce such effect. Vacuum package got a widely applications in the packing of prepared food, salt sacrificial product, and bean product. However, there are still some problems appearing during actual application:

1. Since there is almost no gas existing in inner environment, packing materials will adhere to the content surface. If the product is angular or fragile, package breakage or damage of inner content becomes very possible in courses of transportation and storage.

2. Pressure difference on two sides of the package material is rather big, which facilitates the transmitting of external gases into inner package. Generally, oxygen and carbon dioxide that can influence the quality of inner content has higher demand for permeability than inactive gases such as nitrogen that exerts no influence to the content. Materials with better barrier property should be employed to reduce oxygen permeance. However, packing costs will correspondingly increase.

3. Vacuum package is not suitable for some food. For example, plucked fresh fruits and vegetables still have expiration, and the vacuum package of them will result in the reproduction of anaerobic bacteria.

Improving on the basis of vacuum package, modified air package (MAP), also called air replacing package and gas filling package, adopts inactive gases such as nitrogen to replace the gas within package. According to the aerobic metabolism characteristics of aerobic microbe, this method realized the purpose of mildew proof and prevention of corrosion and preservation by reducing oxygen density through changing gas ingredients of package, during which physiologic activity, mildew activity and rate of respiration are inhibited. In this process, inactive gas nitrogen is the filling gas and plays the role of maintaining positive pressure of inner package. In addition to protecting inner product through preventing extern gases from transmitting in, nitrogen gas can efficiently prevent content transformation and content breaking under pressure without influencing package appearance and printing effect.

2.Important Test Items of Modified Air Package

In MAP, nitrogen gas occupies the biggest content among filling gases. This is mainly because chemical property of nitrogen gas is inactive and exerts no influence on quality of inner content. Comparing with other packages, besides the basic tests of materials, the following two items should also be tested: the barrier property of materials and the purity of nitrogen gas.

Test the barrier property of materials to nitrogen gas is to avoid obvious decrease of nitrogen density within MAP during storage; since this may cause other gases increase in density and result in quality changing of inner content. At present, material barrier property test to nitrogen gas has not attracted enough attention, and sometimes even be neglected by transiting the obtained oxygen permeability (more popularized) into nitrogen gas permeability. In fact, the ratio of oxygen permeability to nitrogen permeability will vary in different materials; and temperature fluctuation will also influence it. This is caused by material structure, characteristics of gas molecules and their relationship with barrier property on a deeper foundation. Material structure includes polymer chain structure and high polymer aggregation structure. Characteristics of gas molecules mainly refer to the size of molecules and their polarity. Therefore, estimating nitrogen permeability by multiplying oxygen permeability with a proportion factor is incorrect.

When MAP is employed in food package, the purity of nitrogen gas in filling gases should also be noted. The nitrogen gas must be up to pure grade (food grade); and impurity content in the gas must be lower than the safety margin of health. Impurity ingredients of nitrogen gas include O2, CO, CO2, H2 and so on. The content of these ingredients is clearly specified in national standards.

3.Material Barrier property Test to Nitrogen Gas

Although gas permeability can be test with differential-pressure method or equal-pressure method, nitrogen gas permeability can only be tested with differential pressure method. This mainly results from the inactiveness of nitrogen gas. It is rather difficult to realize micro quantity nitrogen density test; and the corresponding sensors are rare. As to equal pressure method, carrier gases are required to carry the test gas (testable gases realized at present are oxygen and carbon dioxide) of micro quantity into the sensor. The contradiction is that if the carrier gas presently used is nitrogen gas, it must changes into another kind if the test gas is also nitrogen gas. And this results in more difficulties in aspects of testing costs, conveniences of obtaining carrier gas, and tail gas treatment. Therefore, even if sensor technology for micro quantity nitrogen testing has realized, economical efficiency of equal pressure method for nitrogen gas permeability is still doubted. Taking all this into consideration, nitrogen gas permeability should be test with physical test method- differential pressure method; and the chemical test method should be abandoned.

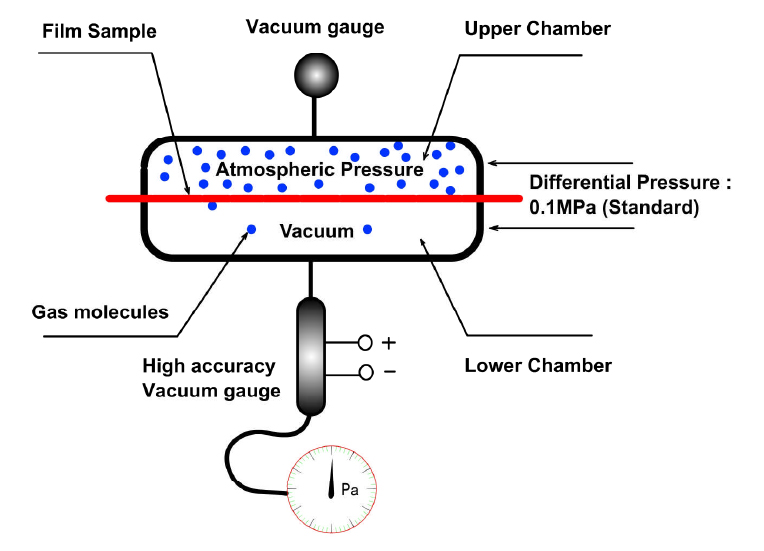

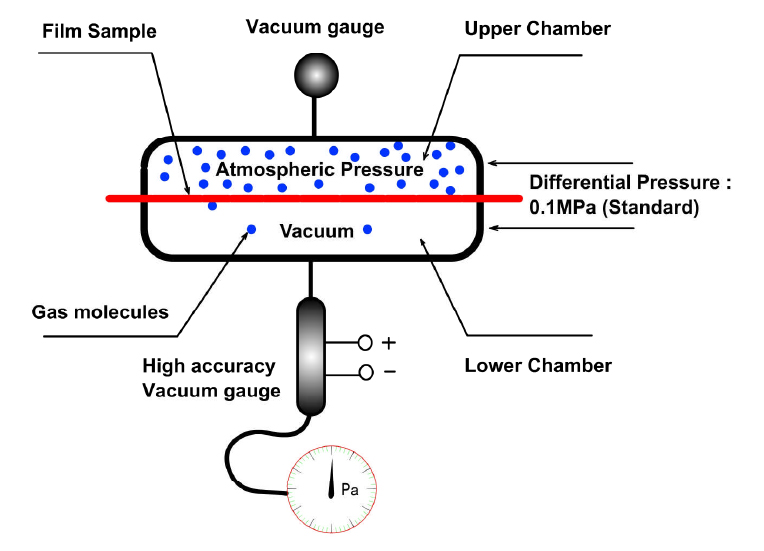

The principle of differential pressure method is simple and clear. In this method, a pressure difference of 0.1Mpa is formed on two sides of the specimen. After the transmitting process has become stable, calculate barrier property of material with the obtained pressure variation of lower chamber. There is no specific requirement to the property of test gas, and gas consumption is very small. This method can be employed if there is no corrosive gas (eroding pipeline and chambers). To some gases, other factors like test environment, trail gas treatment and safety of gas density should also be considered. Being one of the basic methods for nitrogen permeability test, differential pressure method has the advantages of better repeatability of the equipment, multi-purpose and no consumed components. Moreover, vacuum method (typical one of differential method, see figure 1 for test principle) can also test solubility coefficient and diffusion coefficient of nitrogen gas within materials.

Fig.1 Test Principle of VAC-V1 Gas Permeability Tester

4.Conclusion

For The popularizing and application of new packing forms like MAP, nitrogen gas permeability is gradually attracting more attention. It is unacceptable to obtain nitrogen gas permeability through calculation of oxygen permeability. At present, differential pressure method is the only way for nitrogen gas permeability test.