Heat Sealing Technology and Important Testing Indexes

1. Heat-sealing Technology

Heat-sealing package is widely used in the fields of daily chemical products, food and medicine. Since leakage usually appears in the heat-sealing place of package during the process of product filling. And most of the disruption in actual using also appears in the heat-sealing part. The proper choosing of heat-sealing material and heat-sealing parameters can reduce rejection rate while at the same time efficiently improve general permeability of package.

In the process of hot pressed sealing, material of the seal place is heated up to reach a viscous state to be pressed. The sealing is usually finished with hot pressed device or machine. According to the structure and form and heating method of the executive component, i.e., heat sealing head, of hot pressed sealing, hot pressed sealing can be divided into the following methods: common hot pressed sealing, blow out sealing, impulse sealing, supersonic sealing, high frequency sealing, induction sealing and so on. Film with different property will choose different method of hot pressed sealing. For example, supersonic and high frequency sealing is more suitable for film that can be easily heated and transformed. However, the most commonly used hot pressed method is common hot pressed sealing, which can be further divided into flat plate, disk, tape and glide lamella heat sealing. Among that, flat plat heat sealing is the most widely used one.

2. Heat Sealing Parameters

Heat-seal-ability of material including two aspects: hot tack being tested while the sealing place is still hot (not declined to environment temperature) and ultimate strength being tested after the heat seal is cooled down and become stable. The two parameters should be synthetically tested during the evaluation of material heat-seal-ability. It is commonly believed that heat-seal-ability of material is mainly determined by the temperature, pressure and time of heat sealing. Among that, heat-sealing temperature is the most critical parameter and ultimate strength is the foundation of judging heat-seal-ability.

Since the interval between heat sealing package making and content filling in production line is very short and the content is often filled while heat seal temperature has not declined to normal temperature. If strength of heat-sealing part cannot resist the disruptive force of filling content, there will be fracture package. The phenomenon of fracture package is very common in high-speed vertical package production where a package is sealed after it has been filled. Of course, the phenomenon also exists in low speed package machine when heat seal is not completely cooled down.

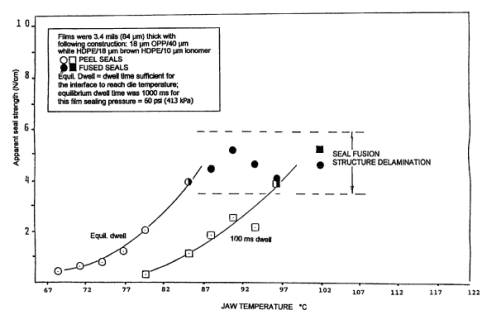

Hot tack describes the ability of heat sealed material to hang together under outsider force within a short time after it has been sealed (not be cooled down yet). It is believed technologically that hot tack is the summarization of sealing agent ‘s tack strength under heat-sealing temperature and the adhesive intensity to multiplayer structure and other component. Under normal condition, hot tack of material after being cooling down is worse than its ultimate strength, which can be obviously seen from fig.1(from standard ASTM F 2029-00) The curve marked “ Equil. dwell ” on its left is the curve of seal strength and temperature tested after the heat sealing film has been completely cooled down(it is noted in the figure that equtemperature tested after an interval of 100ms(not fully cooled down) of the heat sealing part . Although thesilibrium dwell time was 100ms). The curve marked “ 100ms dwell ” on its right is the curve of ultimate strength and e two curves have similar tendency, the hot tack of material tested after an interval of only 100ms is much lower than that tested after being completely cooled down.

Fig.1 testing of Heatsealability

3. Failure Mode of Heat Sealing Specimen

Ultimate strength of material is the peeling force needed by per unit width of heat-sealing layer (such as the failure modes illustrated in figure 2a). However, in actual testing, abruption is always at the nonsealing part instead of the heat-sealing layer. So actual ultimate strength of material is a little bigger than the tested result. Failure mode of material in ultimate strength testing is important information in evaluating specimen heat-seal-ability. Operators should carefully observe the material condition after the testing is finished.

Failure mode describes how testing collet is disconnected when being divided in the process of ultimate strength testing of specimen. Generally, the following mode of failure is identified: peeled seal(figure 2a),cohesive failure of material(figure 2b), break in seal layer(figure 2c), material break(figure 2d), material break/tear(remote)(figure 2e), material elongation (figure 2f), elongation of peeled material(figure 2g).

Note: figure is from ASTEM F 1921-98

Fig. 2Failure MODE of Heat Sealing Specimen

Correct determination of specimen failure mode can exert direct influence on the selection of heat-sealing temperature in actual production. Usually the temperature interval of heat sealing curve is between 5 ~ 10 °C . Specimen failure mode under each temperature should also be explained in detail (usually in the form of graphic illustration, please refer to figure 1). Under normal condition, heat seal temperature should be close to the melting temperature of heat-sealing layer, which is the corresponding temperature of peel part where heat sealing curve rapid increases and of stable part where the turning point happens. If the tested material will be fuse sealed, heat-sealing temperature should be chosen in a temperature range higher than the turning point. If specimen is used in strippable sealing, it should be chosen in a temperature range lower than the turning point. Such specimen should also carry out ultimate strength testing.

4. Conclusion

by the adjusting of heat-sealing parameters, materials can reach an optimal effect of heat-sealing. With the constant improving of package technology, our requirement for the heat sealing quality of material is no longer confining to the firm sealing only, opening easiness during product using is becoming another aspect of package that attracts the consumer's attention.

Link:http://service.labthink.cn/en/article-literature-info-110118104.html

Labthink Copyrights. Please do not copy without permission! Please indicate source when copy.

Relating Articles

- The Analysis on Causes of Flexible Package Breakage and Corrective Methods

- The Relationship between the Hot Tack of Packaging Material and Filling Efficiency

- Testing Sealing Capability of Flexible Package Bags Using LSSD

- Test of Package Develops with New Requirements

- Gas Barrier property Testing of Complex Film

Member Registration and Login In

| If you are already a member of us, please login in! | If you are not a member of us, please register for free! | ||

·Forget password? |

|

·Terms and Conditions If you have questions, please phone 86-531-85811021 |

|