Oxygen Permeability of Contact Lenses Materials

Speaking of contact lenses, the most common thing we thought of is their 'contact' effect. Contact lenses correct vision by directly adhering to the surface of eye cornea to change diopter. Therefore, they possess a lot of unique merits comparing with frame glasses. For example, it applies no compression to nose bridge and ears, and is especially applicable to some special professions such as actor and athlete. Actually, the functions of contact lenses are not limit to the correction of shortsightedness, farsightedness and astigmatism. They have other functions such as treating color blindness and some ophthalmocace by medication absorption.

1. Material Requirements of Contact Lens

Wearers attach particular importance to the selection of lens material because it adheres directly to eye cornea. With the influence of advertisement, many wearers go in for lenses of high moisture content in selecting contact lenses. In their eyes, the higher the moisture content, the better the lens quality. In fact, the pursuit of higher moisture content is very wrong in contact lens selection. Wearers should also take secretory volume of tears, working and living environment into account. Actually, oxygen permeability of lenses is the most important index. The discomforts and wearing time mainly depends on lens oxygen permeability. Moreover, higher moisture content and ultra thin that are advertised now are to improve lens oxygen permeability.

Oxygen deficit, which is caused by inability of eye cornea to obtain oxygen, is the most common trouble of wearing contact lenses. Originally, cornea breathes by obtaining oxygen from air directly. When contact lens adheres to eyeball surface, oxygen can still transmits through lenses, but the transmitting rate reduces obviously. Newly increased vessel caused by cornea oxygen deficit will appear as red heron and will increase the opportunity of infection of eyes. For that reason, contact lenses of higher oxygen permeability should be selected. Oxygen permeability of lenses is related with lens moisture content and lens thickness because oxygen is transmitted by water. However, the crucial factor that influences wearing effect is whether contact lenses match eye cornea.

2. Oxygen Permeability Testing

As mentioned above, oxygen permeability of contact lenses has a direct influence on wearer comforts and will in turn affect the sales. That is why oxygen permeability testing attracts particular attention of lens manufacturers.

ISO issued special testing standards for the oxygen permeability testing of contact lenses: ISO 9913-1 Optics and Optical Instruments-Contact Lenses-Part 1: Determination of Oxygen Permeability and Transmissibility with the FATT Method and ISO 9913-2 Optics and Optical Instruments -Contact Lenses-Part2: Determination of Oxygen Permeability and Transmissibility by the Coulometric Method. Testing principal and testing instruments in ISO 9913-2 is very similar to that used in coulometric method in oxygen permeability testing of flexible material. Many manufacturers of contact lens have been authorizing Labthink to test the oxygen permeability of lens materials and have got ideal testing results.

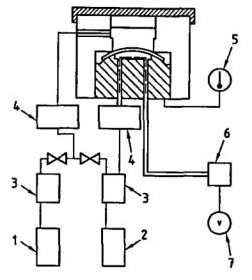

ISO 9913-2 is suitable for rigid and non-hydrogel flexible contact lens materials. The testing indexes are oxygen flux-j, oxygen permeability -Dk, oxygen transmissibility-Dk/t and specimen thickness-t. Generally, Dk is used to evaluate the permeability index of contact lenses. Testing principle is illustrated as fig. 1: put specimen into testing chamber to divide the chamber into upper and lower parts. Fill testing gas into upper chamber with the oxygen content at a fixed rate. Carrier gas flows into coulometric sensor from lower chamber, by which an equal pressure between two sides of the specimen is maintained. However, oxygen partial pressure is different. Under the function of partial pressure, oxygen will transmits into carrier gas through film and will be carried into coulometric sensor, where oxygen quantity in nitrogen gas can be calculated accurately and then oxygen transmissibility of the material can be calculated. Oxygen permeability instrument should be calibrated with reference film before testing to determine the calibration factor, which will be used in calibration. It is regulated in standard ISO 9913 that calibration specimen SRM 1470 is the same as that used in standard ASTM D 3985 for film testing.

Fig.1Testing Principle

Note: 1. Air source 2. Carrier gas 3. Air desiccator 4. Humidity controller 5. temperature controller 6. Coulumetric sensor 7. Voltage recording device

Testing process includes the following steps: purge system, diverge oxygen gas into upper chamber, sensor output becomes stable (judging whether transmitting achieves equilibrium), and obtain testing result. There are mainly two differences between testing of contact lenses and flexible package testing: one is the specimen fixture, specimen shape and area; the second difference is testing environment. Testing temperature of film oxygen permeability is 23℃. To simulate practical service condition, testing temperature of contact lenses is 35℃. Since temperature fluctuation has an obvious influence on testing results of oxygen permeability, the stability of testing temperature is of great significance. Therefore, it is better that the instruments possess function of temperature controlling, just as Labthink TOY-C2 Oxygen PermeabilityTester.

3. Influence of Lenses Suitability on Oxygen Permeability

Whether contact lenses are suitable mainly depends on the perfection of suitability. A pair of good contact lenses should match with eye cornea perfectly. There is a layer of tear existing between contact lens and eye cornea, and is constantly flowing. The tears bring oxygen to cornea and take off waste substance. In this way, contact lenses will not change the normal physiological condition of eyes and will not impair eye cornea. If the contact lens doesn’t match well with eye cornea, even ultra thin lenses of high moisture content will adhere closely to the cornea with the result that the flowing of oxygen can only rely on moisture content and thickness of the lens. Of course, high oxygen permeability is always favorable, no matter what the kind of suitability is.

4. Conclusion

Oxygen permeability of contact lens, which has a direct influence on wearing comforts, is an important index. That is why manufacturers of various contact lenses are trying their best to improve oxygen permeability of contact lenses. At present, the marketing of PGP has obviously influenced market share of traditional flexible contact lenses. The outstanding merit of RGP is high oxygen permeability, which makes no oxygen deficit of eye cornea. With RGP, many complications caused by flexible contact lenses can be avoided. Therefore, RGP has become known and encouraged by most experts.

Link:http://service.labthink.cn/en/article-Permeation-info-11011897.html

Labthink Copyrights. Please do not copy without permission! Please indicate source when copy.

Member Registration and Login In

| If you are already a member of us, please login in! | If you are not a member of us, please register for free! | ||

·Forget password? |

|

·Terms and Conditions If you have questions, please phone 86-531-85811021 |

|