Two Criterias for Evaluation of Permeability Testing Instrument -- Data of “Blank test” and Repeatability of Test Results

With the increase of the number of instrument manufacturers, more and more new gas permeability testing instruments and test methods are emerging. There do exist some differences between test results of individual instruments. Under this objective condition how will we face with these data systems and which instrument should we choose? To solve this problem we should know about the keys of affecting gas permeability.

1. Influencing Factors of Permeability testing

There are many influencing factors in the procedure of permeability testing, such as precision of sensor, effective measuring range, leakage of system, treatment of samples, property of material, test environment, hardware and software design and so on. Among these influencing factors many are from the inborn features of designing. To the application, users do not care about how manufacturers optimize the design, they care about whether they can obtain accurate test results. In this article two important evaluation criterias are introduced- data of “Blank Test” and repeatability of test results.

2. Data of “Blank Test”

2.1 “Blank Test”

“Blank Test” reflects composite error of an instrument. Since some influencing factors do exist and cannot be removed effectively in gas permeability testing, for example system leakage and other unpredictable factor. These factors lead to measuring error. Although the “Blank Test” is not specified definitely in permeability testing standards, the relative test work of “Blank Test” has got widely social recognition.

In order to obtain the composite influencing values of all factors, a fully gas-proof specimen is tested with normal operating procedure on VAC-V1 gas permeability instrument. So we can analyze the composite effect of system leakage and other factors upon the instrument. It's more reliable for us to use the data of “Blank Test” coming from this method to evaluate the instrument.

2.2 Data of “Blank Test” Using VAC-V1

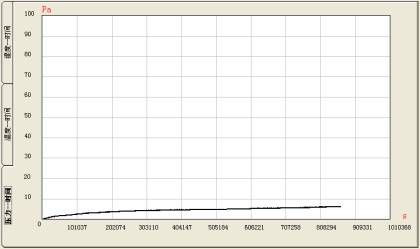

For the “Blank Test” using Labthink VAC-V1 a piece of copper foil specimen 55 μ m thick is used (or thicker aluminum foil). This specimen is tightly sealed between upper and lower chamber. For the test volume we select the normal volume (VAC-V1 has another optional extended volume mode). First apply vacuum to the system for 48 hours (Before test mode begins the degree of vacuum in either upper chamber or lower chamber shall be below 10Pa). The temperature self-control function of this instrument doesn't put into service so that we can analyze how environmental temperature affects tests. The pressure-time curve of this test is shown in Figure1. (In addition this instrument shows temperature-time curve and humidity-time curve, this article omits them.)

Figure1. Pressure versus time

This test lasted for 12 days(time of applying vacuum included) in the condition of temperature 18 ~ 23 °C , humidity 50 + 8% RH(if the temperature self-control function of the instrument the test effect will be even better). The pressure in the lower chamber rose 6.0 Pa from after entering test state to the end and the test result is 0.023ml / m2·24h · 0.1MPa(if we select the extended volume mode or fuzzy test mode, the composite influence of the above factors will be effectively reduced and the test result will be more accurate.) From the test curve and data sheets we can see that the influence of fluctuations of temperature and humidity is very little upon the test.

In the first 60 hours, the change of pressure was relatively big, rising from 0 Pa to 3.84 Pa; in the next 60 hours, the increase rate of pressure decreased, the corresponding gas transmission rate is 0.012 ml/m2·24h · 0.1MPa. Why does this happen? This is relating to degassing process. Actual tests have proved that extending the time of applying vacuum can effectively reduce the influence upon test results.

3. Repeatability of Test Results

3.1 Repeatability Parameters

For instruments using the same test method different manufacturer may choose different elements, so repeatability is an important index in evaluating an instrument. By analyzing repeatability of data, we'll know more about the data error and its fluctuations of an testing instrument to improve test efficiency. Repeatability Parameters include: S(standard deviation) , CV(percent coefficient of variation) and LSD (least significant difference between two individual test results based on a 95 % confidence level ).

3.2 Actual testing data

Oxygen permeability tests on five specimens numbering A, B, C, D, E were performed using Labthink VAC-V1 gas permeability test instrument. The test temperature, value of O2GTR and test results, etc of five specimens are shown in Table 1:

Table1. Test Data

|

Specimen |

Thickness μ m |

Actual testing value of O2GTR |

O2GTR (mean) |

S |

CV% |

Test temperature °C |

|

A |

60 |

5.44 |

5.567 |

0.112 |

2.01 |

23.1 |

|

5.649 | ||||||

|

5.612 | ||||||

|

B |

80 |

20.032 |

19.460 |

0.496 |

2.55 |

23.0 |

|

19.17 | ||||||

|

19.177 | ||||||

|

C |

25 |

42.533 |

42.945 |

0.361 |

0.841 |

20.0 |

|

43.10 | ||||||

|

43.203 | ||||||

|

D |

150 |

383.602 |

382.603 |

0.992 |

0.259 |

23.0 |

|

381.619 | ||||||

|

382.587 | ||||||

|

E |

100 |

1203.54 |

1204.01 |

3.96 |

0.329 |

25.3 |

|

1200.31 | ||||||

|

1208.19 |

Note : Unit of O2GTR : ml/m2·24h·0.1MPa

Specimen A and specimen D are supplied by Thailand Packaging Center.

Specimen B is supplied by Germany Mecadi Laboratory.

From Table 1 we can see that standard deviation (S) increases and CV declines with the increase of the value of O2GTR. This reason is mainly that the factor of specimen degassing and composite factors have a greater effect upon the test chamber in high permeability testing than that in medium and low permeability testing.

4. Conclusion

Data of “Blank Test” and repeatability are important criteria for evaluation of gas permeability testing instruments. Measuring error is both determined by the instrument and test principle. Generally speaking, the quality of test results of “Blank Test” has a great effect upon testing of high permeability specimen, the repeatability of test dada is a composite embodiment of data error in any permeability testing range.

Link:http://service.labthink.cn/en/article-Permeation-info-110118130.html

Labthink Copyrights. Please do not copy without permission! Please indicate source when copy.

Relating Articles

- Overall Realization of Comprehensive Mechanical Testing on Pharmaceutical Packaging and Medical Devices

- Further Improvements on Performance of Weighing Method Water Vapor Transmission Rate Tester

- Verification Tests for Barrier Property of Starch-based Biodegradable Packaging

- The Unparalleled Advantages of LystemTM Laboratory Data Sharing System in Application

- To Improve Laboratory Management Capabilities with the Help of Laboratory Data Sharing System

Member Registration and Login In

| If you are already a member of us, please login in! | If you are not a member of us, please register for free! | ||

·Forget password? |

|

·Terms and Conditions If you have questions, please phone 86-531-85811021 |

|