Laboratories

1. Instruments

W3/330 Water Vapor Transmission Rate Tester

OX2/230 Oxygen Transmission Rate Tester

2. Specimen

Fig 1 Edible Oil Bottle

During the long term storage, oil may become deterioration caused by the chemical changes related to atmosphere, sun light and moisture. Thus, the packages for oil should have good sealing and barrier properties, especially the barrier capability against water vapor and atmosphere. Thus, the edible oil bottle, as the packaging agent for oil, should be evaluated for the water vapor and gas transmission performances, so as to determine the barrier properties and provide guidance for manufacturers.

3. Introduction to Testing

The test needs customized package mouth sealing device and longer PU pipe, for specimen sealing and gas cycling inside the specimen.

Fig. 2. Customized Package Mouth Sealing Device & Longer PU Pipe

4. Testing Procedure

4.1 Testing for Water Vapor Transmission Performance

4.1.1 Testing Environment

Place: Labthink Permeability Laboratory

Temperature: 23℃

Relative Humidity: 90%RH

4.1.2 Testing Procedure

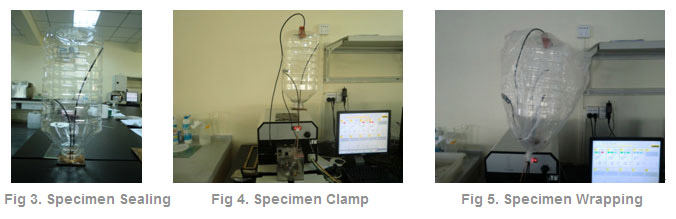

Cover the copper pipe of the package mouth sealing device with the PU pipe. Then, seal the specimen with instant transparent solid glue (Fig. 3). After sealing, clamp onto the instrument (Fig. 4), wrap the parts above the plate with sealing bag (Fig. 5), set the testing parameters and start testing. The test will end automatically, and the results will be displayed on the software interface.

4.1.3 Testing Results

Edible oil bottle WVTR 0.1068 g/(pkg·d)

4.2 Gas Transmission Testing

4.2.1 Testing Environment

Place: Labthink Permeability Laboratory

Temperature: 23℃

Testing Gas: Air

4.2.2 Testing Procedure

Cover the copper pipe of the package mouth sealing device with PU pipe. Then, seal the specimen with instant transparent solid glue (Fig. 6). After sealing, clamp on to the instrument (Fig 7). Set the testing parameters and start testing. The test will end automatically, and the results will be displayed automatically onto the interface of software.

4.2.3 Testing Results

Edible Oil Bottle OTR 0.4693ml/(pkg·d)

| If you are already a member of us, please login in! | If you are not a member of us, please register for free! | ||

·Forget password? |

|

·Terms and Conditions If you have questions, please phone 86-531-85811021 |

|